PRODUCTS

Inclinometers

Geotechnical Monitoring involves the application of multiple geotechnical instruments, each designed for specific function and usage in different conditions. These monitoring sensors are curated to be extremely reliable, durable, and weather-proof in many conditions.

INCLINOMETER

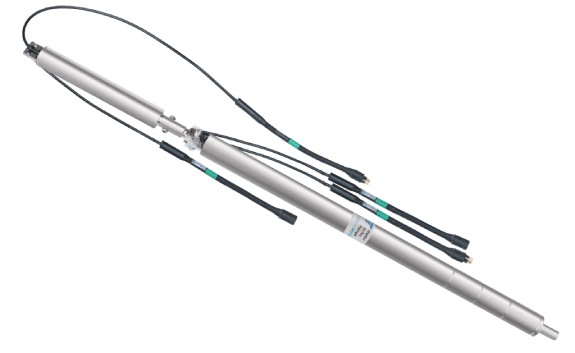

Wireless In-Place Inclinometer (IPI) System

This unit is a wireless in-place inclinometer (IPI) system, designed to measure the lateral movement of earthworks or structures. The IPI is used in critical applications where real-time monitoring and early warning are required in order to protect life and valuable assets.

The in-place inclinometer system consists of a string of digital tilt sensors. The string of tilt sensors is positioned inside the inclinometer casing to span the movement zone. Each tilt sensor is fitted with a pair of pivoted sprung wheels. the unit consists of tilt sensors with SDI-12 output.

The tilt sensors are connected through a single 3 conductor bus cable in a daisy chain fashion, connecting each sensor to its next immediate neighbor and finally to the top of the borehole and directly to a suitable datalogger. This has a great advantages at locations with large number of sensors in a borehole, as it eliminates the hassle to accommodate large number of individual signal cables inside the borehole.

The ESDL-30 datalogger can be used with this IPI system.

INCLINOMETER

3D Inclinometer with Settlement

This in-place 3D inclinometer with settlement (IPIS) system is used wherever lateral movement along with settlement/heave is to be monitored in a borewell or on a structure. It finds wide application in the measurement of lateral movement and settlement in soil, earthworks, slopes or structures like retaining/diaphragm walls, embankment, deep foundations or dams etc. It is also very useful in monitoring landslide areas.

IPIS is designed to provide significant quantitative data on the magnitude of lateral movement along with settlement or heave and its variations with time. It also provides the pattern of deformation, zones of potential danger and effectiveness of construction control measures undertaken. Its data logging and real-time monitoring feature help to provide early warning in case of failures.

The system consists of a string of probes positioned inside the inclinometer casing in a continuous array to span the movement zone. Each probe basically comprises of a high accuracy biaxial MEMS sensor to monitor inclination or lateral movement (X-Y) and a contactless magnetic sensor to monitor settlement or heave (vertical movement-Z), housed in a waterproof stainless steel enclosure. These sensors measure the tilt and settlement in successive segments to accurately monitor a change in the profile (x-y-z) of the inclinometer casing. The real advantage of IPIS is that it allows online monitoring of transverse movement as well as settlement using the same borehole. This was not possible until now using presently available instruments.

INCLINOMETER

Inclinometer Casing & Accessories

The inclinometer casings can be installed in a borehole, embedded in fill or concrete during construction or fixed to the face of a completed structure. These are self-aligning ABS casings with longitudinal keyways at 90˚ for probe orientation.

Inclinometer access tubes are 3 m in length. The casings and couplings (fixed or telescopic) are joined together with pop-rivets. Mastic tape is used over the joints to make a waterproof joint.

Further details of tubing and accessories under ‘find out more’

INCLINOMETER

Vertical Inclinometer

This digital inclinometer system consists of a traversing type digital biaxial tilt-sensing probe and a reel unit. The reel unit contains a winding reel that holds the cable and a wireless Bluetooth relay unit that transmits the probe data to the data logger. A rechargeable battery in the reel unit supplies power to the whole system. Operating cable graduated at every 0.5 m (2 ft) includes a high tensile straining member and is supplied with an easy to carry reel.

The probe is designed to use all standard inclinometer casings i.e. with OD 70 mm (2.75″) & 85 mm (3.34″).

Mobile Readout Unit

The mobile phone readout uses a wireless Bluetooth connection to communicate with the inclinometer reel unit.

INCLINOMETER

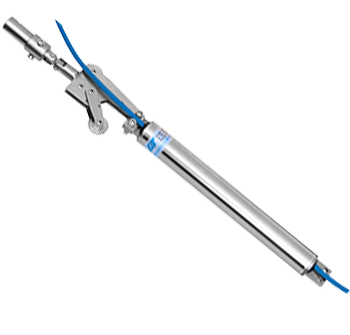

Horizontal Inclinometer

This model is one of the most advanced MEMS digital inclinometer systems of the world. It uses Android mobile phone as a readout and data storage unit so that it is having the high computational power and high-resolution color display capabilities. This system is used to accurately measure horizontal movement including settlement and heave of storage tank, structures, landfills, etc.

The horizontal inclinometer system provides significant quantitative data on the magnitude of settlement and its variation with time. It gives information on pattern of settlement and effectiveness of construction control measures.

This system consists of inclinometer casings with couplings, probe with operating cables and a mobile phone data logger. Accessories like a dummy probe and calibration jig are available on demand.

Note: For vertical inclinometer readings ‘Vertical Inclinometer’ unit is required.

INCLINOMETER

Wireless IPI

This is the most advanced wireless in-place inclinometer (IPI) system, designed to measure the lateral movement of earthworks or structures. The IPI is used in critical applications where real-time monitoring and early warning are required in order to protect life and valuable assets.

The wireless IPI system basically consists of an array of digital inclination sensors, placed inside the inclinometer gage well. The IPI sensor array is interfaced with the wireless network through a Node that allows sensors to send recorded data to the Gateway through a long-range radio frequency wireless communication network. The Gateway then uploads all the collected sensor data to the central/cloud server. This model consists of tilt sensors with both SDI-12 and Modbus output, making it more versatile for different types of dataloggers.

A single 3 conductor bus cable is threaded in a daisy chain fashion connecting each digital IPI sensor to its next immediate neighbor and finally to the top of the borehole and directly to the wireless communication network through a Node. This has great advantages at locations with a large number of sensors in a borehole, as it eliminates the hassle to accommodate a large number of individual signal cables inside the borehole. The wireless system adds to this advantage by eliminating the need for running lengthy cables across large sites.

The design allows each sensor to move independently to each other without influence from the sensors above or below. This provides a profile of displacement over the complete length of the installation.