OUR EXPERTISE, PROJECTS, TECHNOLOGY, AND SERVICES

Strain Gauges

Strain Gauges are one of the vital geotechnical sensors that measure strain in underground cavities, tunnels, buildings, concrete, masonry dams, bridges, embedment in soil/concrete etc. It is a resistance that varies with applied force, as it converts force, pressure, tension, weight, etc., into a change in electrical resistance that is measurable. Stress is determined as the object’s internal resisting forces, and strain is defined as the displacement and deformation that occur.

STRAIN GAUGE

High-Range Embedment Strain Gauge

This series of vibrating wire strain gauges are designed to measure large strains up to 5000 micro-strains.

The embedment strain gage is used to measure strains in concrete mass. It is designed to measure strain in underground cavities, tunnels, buildings, concrete and masonry dams etc.

This embedment strain gauge has stainless steel flanges at either ends and is suitable for embedment directly in concrete. Any deformation in the concrete mass causes the two end blocks to move relative to one another, thus changing the tension in the wire, resulting in a corresponding change in its frequency of vibrations. It is similar to the embedment strain gauge, except that it is used to measure large strains up to 5000 micro-strains. Other models only measure up to 3000 micro-strains.

STRAIN GAUGE

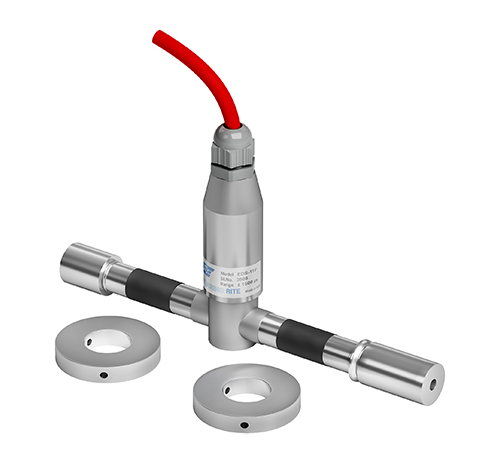

Arc Weldable Strain Gauge

This strain gauge is generally intended for long-term strain measurement and are suitable for surface mounting by welding on steel structures such as bridges, piles, wye sections, pressure shafts, tunnel linings, and supports, etc. The tube is flattened in the middle to accommodate a sensor (coil/magnet assembly) in the construction. To mount the strain gauges, two annular mounting blocks are accurately positioned and aligned by a dummy gauge and welded to the structure. The strain gauges incorporate the latest vibrating wire technology to provide a digital readout on a remote vibrating wire indicator.

This model provides further protection by suitably sealing the joints with heat shrinkable tubes. In addition to this, a special waterproofing compound seals the plucking coil in the sensor assembly from any ingress of water.

STRAIN GAUGE

Low-Range Embedment Strain Gauge

This strain gauge is primarily intended for strain measurement in pile foundations, segment lining of tunnels and concrete structures, etc. It is suitable for soil or concrete. The sensor is made of stainless steel and has waterproofing to prevent any ingress of water.

STRAIN GAUGE

Heavy-Duty Strain Gauge

This unit is highly resilient and reliable strain gauges. It has its suitability for embedment in mass concrete or for surface mounting by welding on steel structures. The sensor is welded in it and hermetically sealed by an electron beam welding technique, generating a vacuum of round 0.001 Torr inside it. Using this technique, any effect of oxidation, moisture, and ingress of water is eliminated. Accessories include a spider for strain rosette, no stress-strain container, dummy strain gauge and extender.

STRAIN GAUGE

High-Range Arc Weldable Strain Gauge

This unit is designed to measure strain in steel or on the concrete surface of the composite structure. It is suitable for surface mounting by welding on steel structures such as bridges, piles, wye sections, pressure shafts, tunnel linings and supports, etc.

STRAIN GAUGE

Sister Bar Strain Gauge

The Vibrating Wire Sister Bar is used to measure strain in concrete structures such as diaphragm/slurry walls, piles, tunnel lining, bridge abutments, foundations, dams etc. It contains of a hollow bar with vibrating wire strain gauge which is coaxially mounted inside it. On the two end sides the hollow bar is extended with 12 mm Ø reinforced bars. This model is also available with a 16 mm Ø reinforced bar variant.

STRAIN GAUGE

Dynamic Strain Gauge

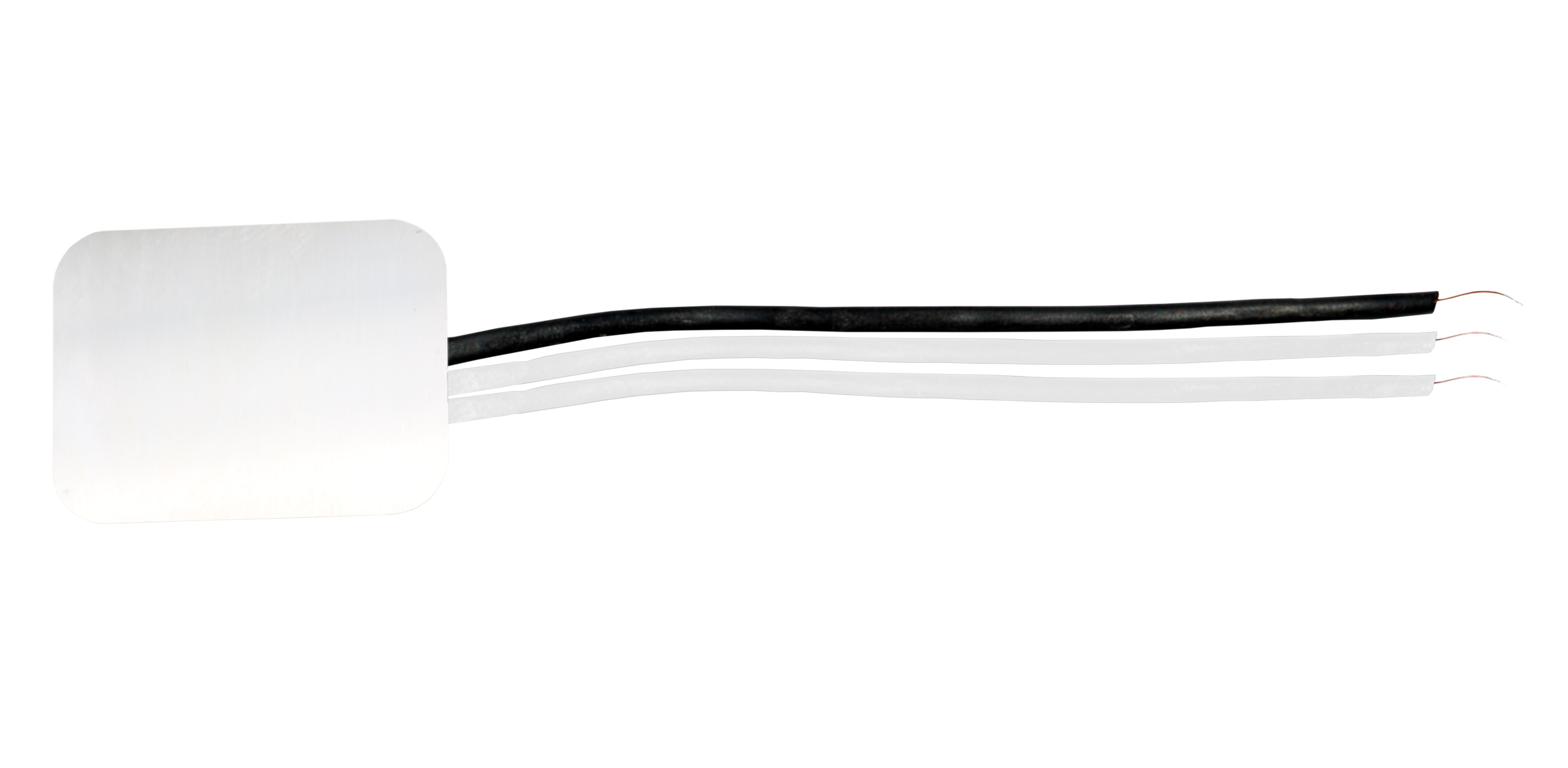

This unit is a weldable strain gauge, a precision strain gauge with high frequency response for dynamic strain/stress monitoring. It is commonly called dynamic strain gauge. Dynamic strain gauge plays a vital role in measuring structural health monitoring. It is specially designed for installation on the structural steel membrane, on which the stress/strain needs to be monitored, by spot welding. The strain gage generates a bridge signal output (mV/V) proportional to the stress on the structure.

The weldable strain gauge is a strain gauge of choice over vibrating wire strain gauges in applications where stress changes very fast and dynamic monitoring is required. This unit offers the provision of waterproof installation, the dynamic strain gauge are most suitable ones for long term reliability, when installed in hostile environments such as in bridge applications.

Various choices of datalogger is available to collect and transfer strain gauge data to central server.

STRAIN GAUGE

Spot Weldable Strain Gauge

The vibrating wire strain gauge can be spot welded or epoxy bonded on steel structures and struts. It can also be epoxy bonded on concrete structures. A sensor coil housing mounted directly over the strain gauge, completely encloses the sensor, forming a watertight enclosure. A pair of clamps are provided to aid in fixing the housing to the substrate using an epoxy adhesive.